| Architect |

Hopkins

Architects |

| Date

Built |

2004 |

| Location |

Euston Road |

| Description |

|

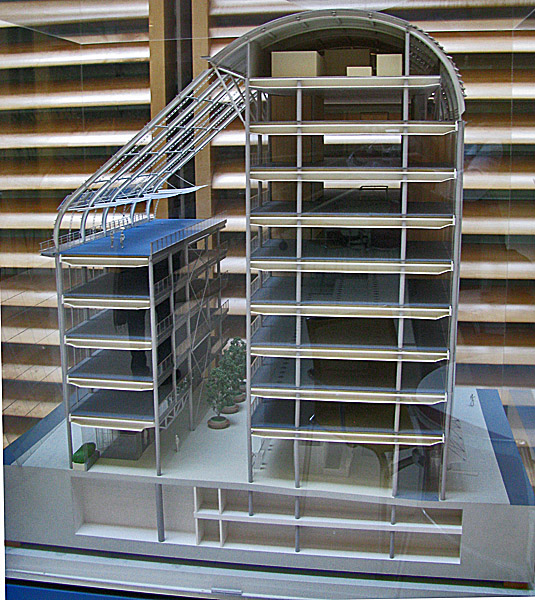

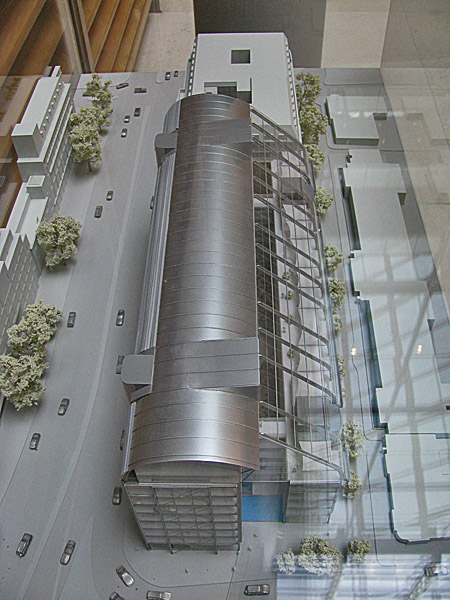

The

headquarters building of the Wellcome Trust

occupies a site on the corner of the Euston

Road and Gower Street. The building is

known as the Gibbs Building, named after the

Trust's former Chairman Sir Roger

Gibbs. The Trust describes the

building as consisting of, " ... two

blocks of accommodation - one wider, of

eight stories, facing Euston Road to the

north, and a narrower four storey

parallel block to the south. Over both

is a curving glazed roof, enveloping a

generous atrium between."  " ... each floor

of the northern block has five

separate large flexible working floor

areas. These are linked with break out

spaces and double height 'mini atria'

for casual interaction between team

members. The narrower southern block

offers more intimate space for

individual offices. On its top floor,

open to the roof and atrium, there is

a restaurant with views across

Bloomsbury. Double

skin, glazed façades create an

environmental buffer between inside

and out. Translucent glazed stair

towers articulate the internal space.

A new Headquarters

brings 600 staff together in an

inspiring, comfortable and dynamic

workspace."

|

|

**********************

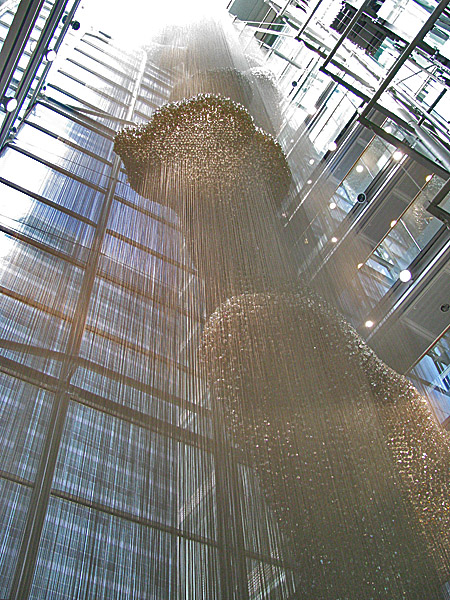

Bleigiessen - by the Thomas Heatherwick Studio

The Thomas Heatherwick Studio

won a competition in 2002 to create a major

sculpture for the new building. The Trust

had a desire for a sculpture that would, "

... complement the cool but dramatically

deep space allocated for it", on the

Gower Street end of the atrium. Since none

of the entrances were wide enough to bring in a

sculpture that would fill the allocated space,

in true Heatherwick style, they decided to

create one that could enter through the

letterbox. Heatherwick Studios say that, "The

vertical void seemed almost like a gravity

chamber, and the pool of water at the base

was a catalyst to thinking that led Thomas

Heatherwick and his colleagues to experiment

with liquid. He says, 'The aim was to

produce a sinuous, curvaceous form, and one

that had variety, so it would look different

from each of the building's nine floors."

The development process involved dropping hot metal into water and creating twisting tumbling forms as the metal cooled. Once they had selected their favourite metal shape they scanned it in three dimensions. The name Bleigiessen comes from the tradition in Germany of dropping hot lead into water at New Years to create forms which can be read like tea leaves to forecast your fortune in the coming year.

Heatherwick's mother was the founder of the Bead Society of Great Britain and this gave him the idea of replicating the form using glass beads strung on wires. "Working closely with British company, Flux Glass Design Ltd, Thomas Heatherwick Studio designed a glass bead, a transparent sphere that would subtly change colour and vary in brightness as you move in relation to it, and that would throw patterns of light on to surrounding walls. To create the sculpture almost 27,000 very fine stainless steel wires (0.5 mm in diameter and 30 m long) were threaded with glass beads (over 140,00 of them weighing almost 40 tonnes)." The end result can be seen below.

The development process involved dropping hot metal into water and creating twisting tumbling forms as the metal cooled. Once they had selected their favourite metal shape they scanned it in three dimensions. The name Bleigiessen comes from the tradition in Germany of dropping hot lead into water at New Years to create forms which can be read like tea leaves to forecast your fortune in the coming year.

Heatherwick's mother was the founder of the Bead Society of Great Britain and this gave him the idea of replicating the form using glass beads strung on wires. "Working closely with British company, Flux Glass Design Ltd, Thomas Heatherwick Studio designed a glass bead, a transparent sphere that would subtly change colour and vary in brightness as you move in relation to it, and that would throw patterns of light on to surrounding walls. To create the sculpture almost 27,000 very fine stainless steel wires (0.5 mm in diameter and 30 m long) were threaded with glass beads (over 140,00 of them weighing almost 40 tonnes)." The end result can be seen below.

Close Window